Structural glass – ubiquitous in office and high-rise residential developments in big cities – is now being used on a wide range of less high-profile but structurally innovative residential projects.

The strength needed, as well as the need for excellent acoustic, solar, thermal, and security performance, means that as glass panels become bigger, they become extremely heavy.

Hird Group is playing a key role in helping glass installation specialists as they race to keep up with new ways architects are finding to use large structural glass panels in homes.

It supplies some of the UK’s most advanced and innovative glass lifting equipment and mini cranes. If necessary, Hird works with manufacturers to design glass vacuum lifters for specific developments.

Hird Director John Wilding said: “Our whole approach is to make glass lifting safer, more productive, and easier to manage, while minimising the risk of damage to glass panels and structures.”

The range of equipment falls into three main categories – glazing robots, glass vacuum lifters, used in conjunction with mini cranes, and less sophisticated but highly-effective material lifts.

Winlet glazing robots are among the most impressive Hird glass lifters. Maximum loads can reach one tonne. Glass can be installed directly overhead. And Winlets can lift any non-porous sheets, even glass reinforced concrete sections.

At the super-heavy range is the Kappel 3500, known as Brutus. Combined with a mini or mobile crane, it can lift sheets up to 3.5 tonnes. Other vacuum lifters are specifically designed to lift curved glass.

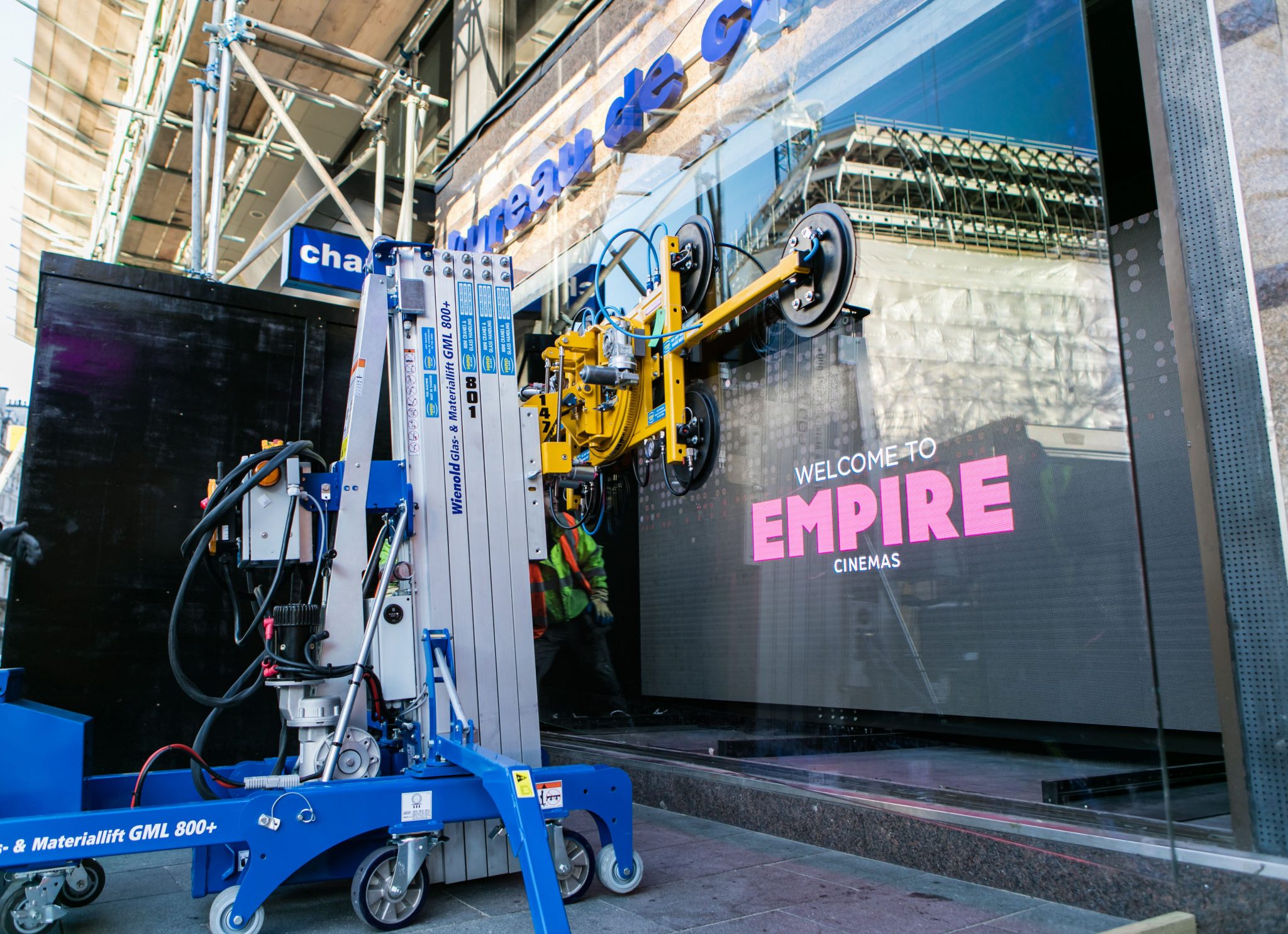

Keeping things simple is the GML 800+ counterbalance floor crane. It is easy to use and can be fitted with vacuum lifter to install glass weighting up to 800kg at heights up to 7.9m.

John Wilding said: “Architects are known for seeking to achieve a wow factor with their designs. The capabilities of our glass lifters also get people stopping and staring. It’s a case of seeing is believing.”

0203 174 0658