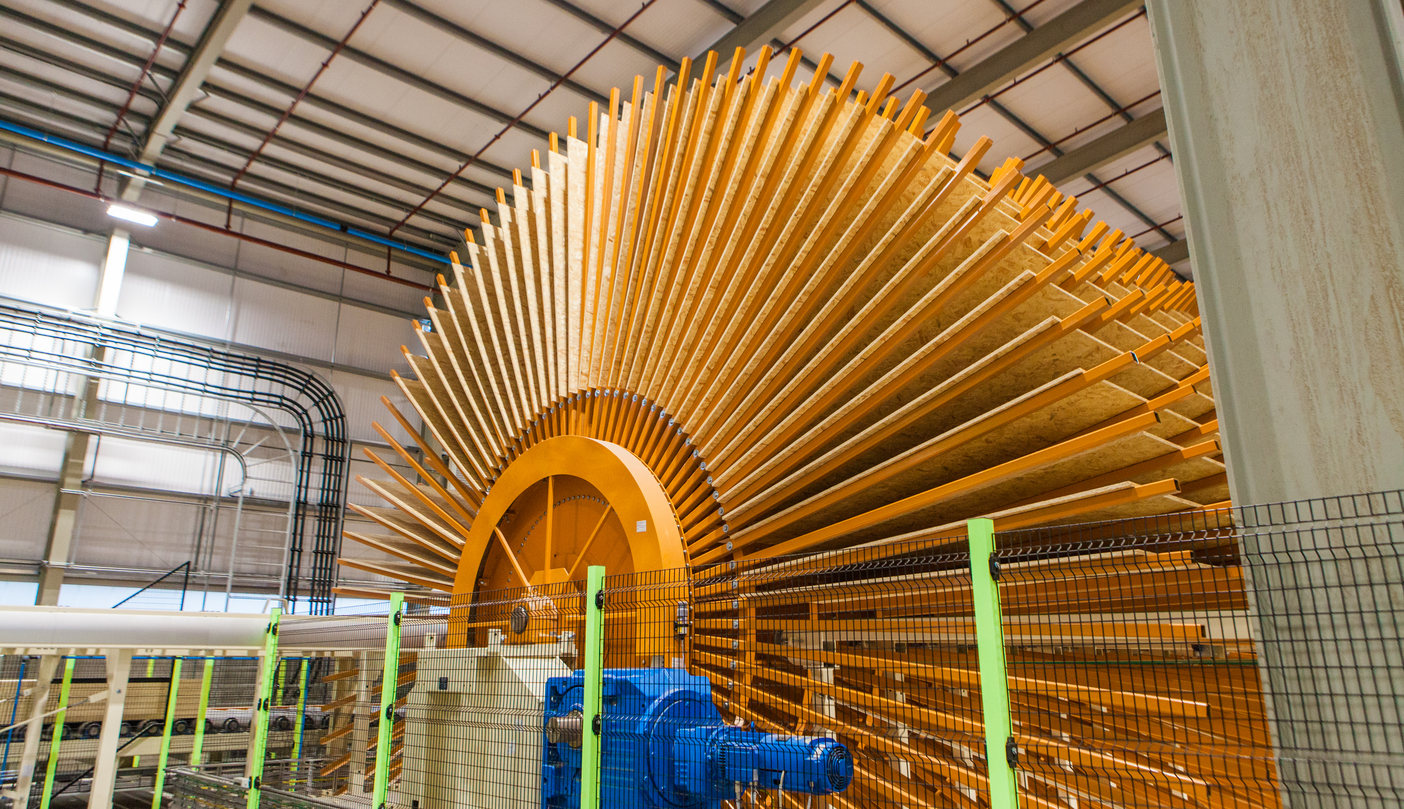

West Fraser’s SterlingOSB Zero production, Inverness

One OSB product may seem much like any other. In reality it is worth checking before specifying, especially if you want to score eco points. When it comes to being green, West Fraser’s SterlingOSB Zero stands out. Not only is SterlingOSB Zero the only UK-manufactured OSB with zero-added formaldehyde, but it is also net carbon negative.

OSB, or Oriented Strand Board to give it its full name, has become ubiquitous and is often used as a substitute for chipboard and plywood in applications such as flooring, roofing and timber framing. There is good reason for this. OSB is versatile, easy to use and with high consistency and board strength has no weak spots. SterlingOSB Zero or ‘Sterling Board’, as it is often known, is one of Europe’s most widely used and trusted structural panels.

In simple terms, OSB is formed of flakes or strands of timber bonded with resin adhesives in some 50 cross-directional layers. These are then mechanically pressed to create a structurally engineered board.

Resins used to bind the flakes of SterlingOSB Zero contain zero-added formaldehyde. With less resin and more wood, the boards are more environmentally friendly and safer while performance is unimpaired.

The other important way that West Fraser’s SterlingOSB Zero can help specifiers and builders towards their environmental targets is that the boards do not contribute to climate change; they are certified carbon negative.

In-depth life-cycle assessment of carbon emissions in buildings is increasingly resulting in the building sector being advised to design and build with wood. As wood naturally absorbs carbon as part of its natural life cycle, it is an ideal replacement for other materials with high levels of embodied carbon such as concrete and steel.

The UK government has pledged to be carbon neutral by 2050. This target will require the UK to bring all greenhouse gas emissions down to net zero. SterlingOSB Zero products can help the construction industry comply; the net carbon negative status of the boards can be used by building designers to off-set the operational emissions of a building.

Every SterlingOSB Zero board removes more carbon from the atmosphere than is emitted during manufacture, locking it up into long term storage within the board. Per cubic metre, SterlingOSB Zero sequesters 828kg of CO2e. The wood used is homegrown, minimising carbon emissions from transport while ensuring it is always available and offers a cost-effective building solution.

West Fraser is a diversified wood products company with more than 60 facilities in Canada, the United States, the United Kingdom and Europe. From responsibly sourced and sustainably managed forest resources, West Fraser produces lumber, engineered wood (OSB, LVL, MDF, plywood, particleboard), and other products including pulp, newsprint, wood chips and renewable energy. West Fraser’s products are used in construction, repair and remodelling, industrial applications, papers, tissue and box materials.

For further information call 01786 812 921 or visit Uk.westfraser.com