Overview

Commercial to residential, it may be last orders for some of our great British pubs, for other’s its discovering exciting ways of transforming commercial structures into luxury residential dwellings. The growing trend of converting old inns offers new homes a unique history whilst being packed with character and features.

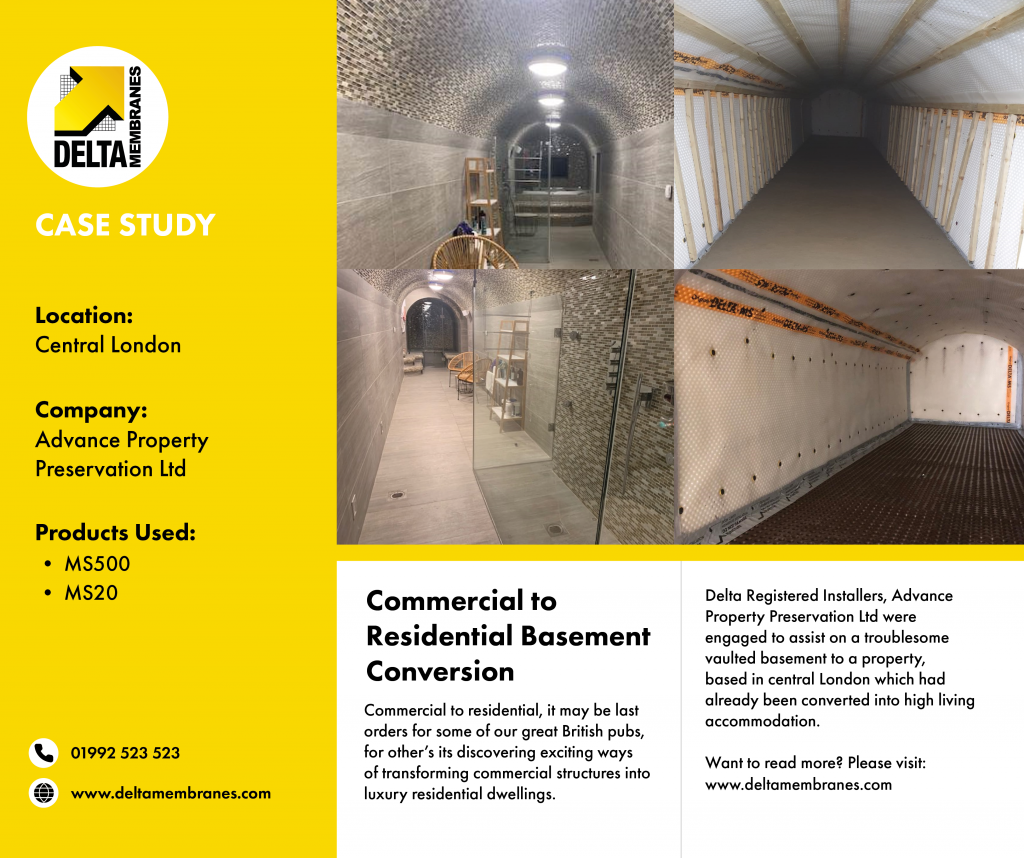

Delta Registered Installers, Advance Property Preservation Ltd were engaged to assist on a troublesome vaulted basement to a property, based in central London which had already been converted into high living accommodation.

Just off the basement area were two large vaults around 12m long. Made from brick barrel construction, this below ground space had previously used for storing kegs of ale!

One of these vaults had previously been converted into a spa area with jacuzzi and steam room, the other was used as a storage area. The owners had previously had the storeroom tanked with a Type A, render system, however this approach repeatedly failed, allowing for substantial water ingress which was causing damage to items stored in this area.

With Structural Waterproofing one of the major contributors to project failure lies with the design. When hiring contractors, ensure the design, procurement of materials and installation is undertaken by one specialist will naturally reduce these known and associated risks. A specialist contractor will always be able to offer quality assurances.

Methodology

Consideration to the grading of the structure (habitable requirements in this instance) is key to specifying an appropriate waterproofing system.

For Grade 3 Habitable environments, two systems of waterproofing may be required.

For Grade 2, Habitable environments, only one form of waterproofing may be required, but caution should be applied because different stored items require very precise environments.

Prior to any product specifications, Advance Property Preservation Ltd firstly undertook thorough site investigations. This initial investigation allows for important ‘cross-checks’ to ensure any proposals will meet not only customer requirements but will also conform to BS 8102:2009, the British Standard which governs the waterproofing industry.

On surveying the site, which was directly below a road it was evident that vibration from traffic was causing the existing render system to crack, which was resulting frequent in water ingress.

Advance Property Preservation Ltd proposed installing the Delta Type C Cavity Drainage System along with mechanical ventilation. The Delta Type C Cavity Drainage System allows for slight movement and vibration without altering the dynamics of a structure.

In principle a Cavity Drainage System allows for moisture or running water to travel behind the membrane in a controlled drainage system. Whilst requiring minimal preparation and disturbance to an existing substrate.

Delta MS 500 was installed to walls and barrelled ceilings, with Delta MS20 loose laid and joined to the MS 500 wall membrane laid to the floor with a protective screed subsequently poured on top. Below the floor membrane perimeter drainage channels were sited within rebates allowing for suitable drainage of any future water ingress and being diverted to suitable discharge points.

It seems natural to focus on the installation itself, Advance Property Preservation also considered the final operation, ensuring the Type C System was serviceable and that future and ongoing maintenance was possible.

After the Type C System was installed, walls and soffits were battened and boarded with moisture resistant plasterboard and plastered over. Once complete the walls were painted with an anti-mould paint, with insulation and timber oak flooring then being laid.

A moisture sensitive, humidistat-controlled fan was fitted as well as new lighting to give the client a new dry storage space.

Case Study Results

The clients were delighted with Advance’s approach.

Any structural waterproofing is a technical and design driven approach. By the customers engaging with Delta Registered Installers, Advance Property Preservation Ltd were able to sequence the works in 3 weeks!! Key matters which significantly impact the efficiency of the site installation were immediately identified in the initial site inspection, allowing for a suitable solution to be created.